Introduction

In Europe, persistently high electricity costs and the rising demand for household energy autonomy have sparked a boom in balcony photovoltaics. The rapid popularity of balcony PV systems across Europe—particularly explosive growth in Germany—can be attributed to their core advantage: easy installation without professional construction. This feature perfectly aligns with European households’ pursuit of energy solutions that are plug-and-play and flexibly deployable.

What’s more, as systems become more widespread, users are placing increasingly stringent demands on fire and explosion prevention as well as stability under extreme weather conditions. Safety has become the core consideration in product selection. From the early dominance of lithium iron phosphate (LFP) batteries to the emerging semi-solid-state LFP batteries, each technological iteration is reshaping the efficiency and safety of energy storage.

With its innovative design and outstanding performance, the SolidFlex 2000 semi-solid-state LFP battery redefines the benchmark for balcony energy storage. The following sections will analyze why SolidFlex 2000 is your ideal choice, based on its core advantages.

1. LFP Batteries: The Foundation of Balcony Energy Storage

Why has lithium iron phosphate (LiFePO₄) become the preferred choice for household energy storage in the balcony sector? The widespread adoption of this battery type is due to the combined effect of three core advantages:

- Safety: The structure of LFP remains stable under high temperatures and overcharging, with a much lower risk of thermal runaway compared to ternary lithium batteries.

- Economy: LFP batteries offer lower purchase costs, reduced lifecycle electricity costs, and nearly maintenance-free operation—making them a cost-efficiency benchmark for household storage.

- Environmental Sustainability: Free of scarce metals like cobalt and nickel, LFP batteries have high recycling rates and meet the green energy demands under carbon neutrality goals.

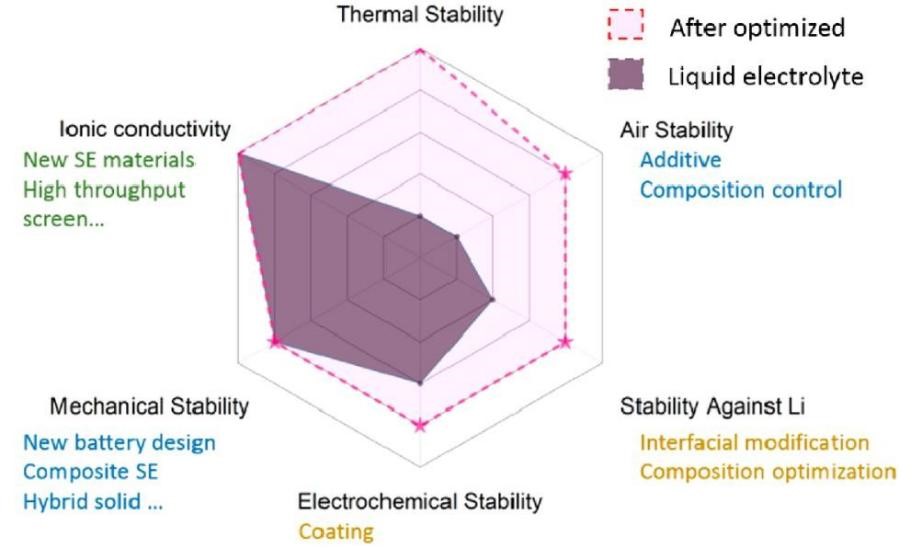

2. Semi-Solid-State LFP Batteries: The Future of Balcony Storage

While traditional LFP batteries continue to dominate the market with their low cost and long lifespan, why is semi-solid-state LFP technology regarded as the future direction?

We will now explore the technical pain points that semi-solid-state batteries address in balcony applications:

Why does battery performance drop in winter?

- Loss of Battery Activity

In low-temperature environments (e.g., below 0°C), the electrolyte inside lithium-ion batteries becomes more viscous, reducing lithium-ion mobility and thus lowering capacity. Conventional lithium batteries can lose about 20% capacity at 0°C, and up to 50% at -10°C. - Suppressed Chemical Activity

Low temperatures cause the electrode surface to become passivated, hindering lithium-ion intercalation/deintercalation, increasing polarization, and significantly reducing usable energy density. - Reduced Charging Efficiency

Lower electrochemical reaction rates at low temperatures slow down charging and may damage battery lifespan if prolonged.

Why do impacts lead to smoke or fire in batteries?

- Internal Short Circuit from Physical Damage

Impact or puncture may rupture the separator, causing the anode and cathode to touch and short-circuit—releasing heat rapidly. Liquid electrolytes (e.g., carbonates) are highly sensitive to heat/sparks and may decompose rapidly, resulting in thermal runaway and potential fire/explosion. - Lithium Dendrites: The Hidden Killer

Prolonged usage or overcharging can lead to dendrite formation in lithium metal anodes, which may pierce the separator and cause internal short circuits. Liquid electrolytes offer limited suppression of dendrites, exacerbating safety risks. - Difficult Thermal Containment

Traditional battery packs transfer heat quickly between cells. If one cell undergoes thermal runaway, it may trigger a chain reaction. Liquid electrolytes spread heat rapidly, making containment difficult.

3. Can Solid-State Batteries Solve These Root Issues?

Solid-state batteries replace liquid electrolytes with solid-state electrolytes, fundamentally addressing the key pain points of traditional batteries:

Revolution in Safety

- Solid Electrolytes: Materials such as sulfides and oxides are heat-resistant and non-volatile, effectively eliminating the risks of leakage and combustion.

- Suppression of Lithium Dendrites: Solid electrolytes have high mechanical strength and can physically block dendrite growth, greatly reducing the chance of short circuits.

- Improved Thermal Stability: All-solid-state batteries remain stable under extreme tests such as nail penetration and compression, with thermal runaway temperatures significantly higher.

Optimized Low-Temperature Performance

Solid electrolytes avoid the viscosity increase seen in liquid electrolytes at low temperatures, maintaining high ionic conductivity even in extremely cold environments.

Breakthrough in Energy Density

By using solid electrolytes and high-capacity lithium metal anodes, solid-state batteries significantly surpass traditional liquid lithium batteries in energy density.

4. Why Aren’t Solid-State Batteries Widely Adopted Yet? Is There an Alternative?

Currently, the cost of fully solid-state batteries is several times higher than that of liquid batteries. This is due to:

- High material costs (e.g., sulfide electrolytes, LLZO).

- Lack of large-scale production capabilities (global sulfide electrolyte capacity is under 100 tons/year).

- Absence of standardized manufacturing equipment.

As a result, full solid-state batteries are not yet mainstream.

The Optimal Alternative: Semi-Solid-State Batteries

Semi-solid-state batteries combine the advantages of liquid and solid-state batteries, making them the most feasible replacement solution.

5. SolidFlex 2000 Balcony Storage System: The World’s First Semi-Solid-State LFP System Leading a New Era

With rising demands for safety and energy density in storage applications, semi-solid-state batteries are rapidly penetrating the market. At the 2025 EES Europe in Munich, INDEVOLT launched a revolutionary semi-solid-state LFP balcony storage system, offering multiple layers of protection even under extreme scenarios:

- In the event of accidental impact or puncture, the solid skeleton limits electrolyte leakage, significantly reducing fire risk.

- During summer heat or enclosed space exposure, internal temperature control is enhanced, preventing thermal runaway.

- Comprehensive upgrades to household storage safety boundaries.

5.1 Extreme Safety Performance: Redefining Storage Safety Standards

Internal Short Circuit Protection (Nail Penetration Test)

When pierced with an 8mm steel needle, the semi-solid-state battery does not smoke, catch fire, or explode. Solid electrolytes suppress dendrite growth, and the low proportion of liquid electrolyte minimizes thermal runaway risk—solving the traditional “penetration equals explosion” issue.

High Temperature Tolerance (Thermal Chamber Test)

In a 160°C thermal chamber, the cell remains stable with no signs of thermal runaway. Compared to traditional liquid batteries, semi-solid technology raises the temperature threshold to beyond 160°C, making it suitable for hot regions and enclosed balconies.

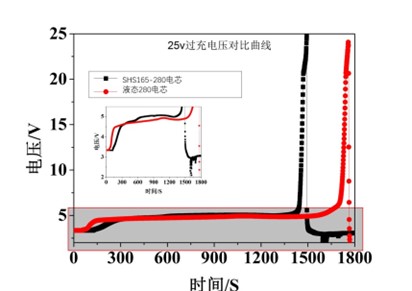

Overcharge Protection (Electrical Safety Test)

Even when overcharged to 25V at a 0.5C rate (far beyond rated voltage), the battery remains safe. Coordinated action between the intelligent CEI/SEI interface layer and solid electrolyte prevents chain reactions and electrolyte gas expansion.

External Short Circuit Protection (Short Test)

When shorted with a <1mΩ wire, the battery shows no signs of thermal runaway. This is due to the battery’s low internal resistance and efficient heat dissipation design, preventing local overheating during short circuits.

5.2 Ultra-Long Cycle Life: Ensuring Economic Viability

Under standard conditions (25°C), the semi-solid-state battery achieves:

- ≥80% capacity retention after 6000 cycles at 0.5P charge/discharge.

- ≥70% capacity retention after 8000 cycles.

This greatly exceeds traditional LFP batteries and reduces lifecycle electricity cost in high-frequency applications like home energy storage and grid peak shaving.

5.3 Safety Comparison: Semi-Solid vs. Traditional Liquid Batteries

Extreme Safety Performance Comparison

| Items | Semi-Solid-State Battery | Traditional Liquid Battery |

|---|---|---|

| Cycle life (70% DOD) | 8000 | 6000 |

| Short circuit after 150°C storage | No smoking, no fire, no explosion | Smoking, no fire, no explosion |

| Overcharge + heat trigger | Trigger at 123°C | Trigger at 97°C |

| Overcharge at 280A | No thermal runaway | Thermal runaway and propagation |

Additional Test:

- Semi-solid cells placed in an explosion-proof box, stored at 150°C for 1 hour, then short-circuited → No thermal runaway observed.

- 13-cell and 52-cell modules overcharged to 5.475V with 280A current → No smoke, fire, or explosion.

Overcharge Test (Single Cell)

| Test | Method | Cell Type | Result | Trigger Time | Temp | Max Temp |

|---|---|---|---|---|---|---|

| Overcharging | 0.5C to 25V | Semi-solid LFP | No smoke | None | None | 89.6°C |

| Overcharging | — | Traditional liquid | Smoke | 1800s | 84°C | 306°C |

- Semi-solid: Smooth voltage curve, max temp 89.6°C, no smoke or runaway.

- Liquid: Smoke after 1800s, max temp 306°C, severe safety risk.

5.3 Continued: Short Circuit & Puncture Test Results

External Short Circuit & Puncture Test Comparison

| Test Item | Test Method | Test Result | Temperature |

|---|---|---|---|

| External Short | Short circuit (≤5mΩ resistance), | No swelling, no valve release, | 31.7°C |

| Circuit | continuous discharge to 0V | no fire, no explosion | |

| 5mm Penetration | 25mm/s puncture through the cell center, | No swelling, no valve release, | 95.6°C |

| held for 1 hour | no fire, no explosion |

- Visual inspection: No significant change in battery appearance before and after short circuit, structure remained intact.

- Puncture results: Battery maintained structural stability, with no bulging or valve ejection—confirming safe performance.

Based on the fact that the battery remains structurally stable after the puncture test, it can be confirmed that it is in a safe condition (no swelling, valve spray, etc.).

Summary: Through parameter comparison and physical comparison diagrams, the safety and reliability of the battery under extreme conditions can be intuitively verified. Both types of extreme tests meet safety standards.

Module-Level Thermal Runaway Trigger Test

Test Method and Objects

Modules with 12 serial cells (no isolation between cells) were heated while monitoring:

- Voltage

- Side temperature (diffusion)

- Pressure relief valve status

- Thermal runaway indicators (smoke, fire)

| Item | Voltage (V) | Diffusion Temp (°C) | Pressure Valve | Thermal Runaway | Result |

|---|---|---|---|---|---|

| Regular Cell | 0 | 311.8 | Yes | Yes | Not Passed |

| Semi-Solid Cell | 3.335 | 81.5 | No | No (light swell) | Passed |

Key Findings:

- Traditional cell: Voltage dropped to 0V, side temperature exceeded 300°C, valve ejected, thermal runaway occurred (smoke/fire).

- Semi-solid cell: Voltage remained at 3.335V, temperature ≤81.5°C, no valve ejection, no smoke/fire, only slight swelling—no thermal runaway.

Conclusion:

Even without cell isolation, semi-solid battery modules suppressed thermal runaway when heated—low temperature rise, no smoke/fire, valve intact, demonstrating excellent thermal safety and system reliability.

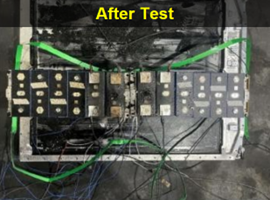

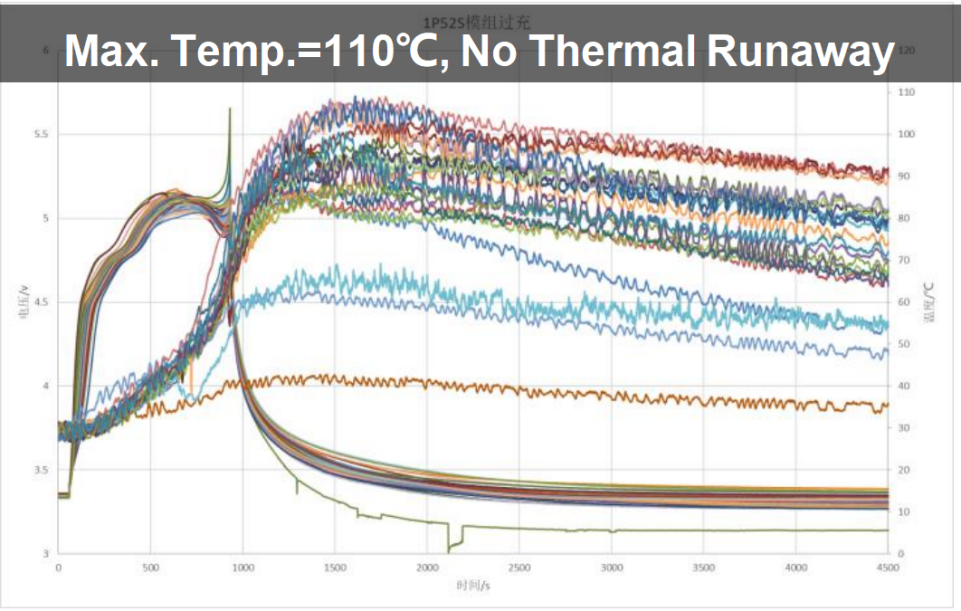

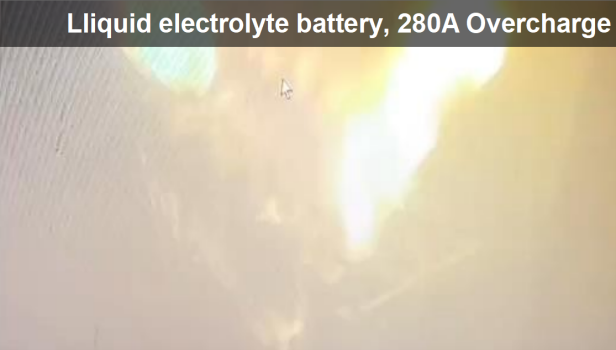

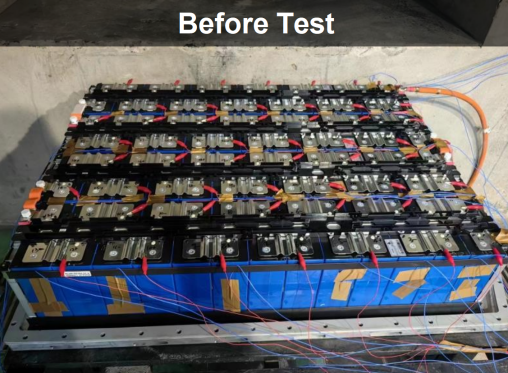

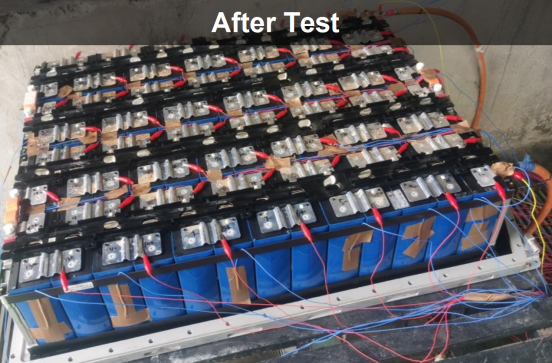

Overcharge Test at Module Level (280A)

Test Description

Both semi-solid and traditional liquid battery modules were overcharged with 280A current. The test compared:

- Thermal runaway

- Temperature rise

- Physical appearance

Results Comparison

Semi-Solid-State Battery Module:

- Temperature: Max 110°C

- Thermal Runaway: None

- Appearance: No smoke or fire; slight cable deformation; structure remained intact

Traditional Liquid Battery Module:

- Phenomenon: Severe fire during overcharge (visible flames)

- Thermal Runaway: Occurred

- Safety: Poor

Conclusion:

Under overcharge, the semi-solid-state battery module maintained:

- Lower max temperature (≤110°C)

- No thermal runaway

- Stable structure

Far superior to traditional liquid batteries, proving its excellent overcharge safety and enhanced reliability in extreme scenarios.

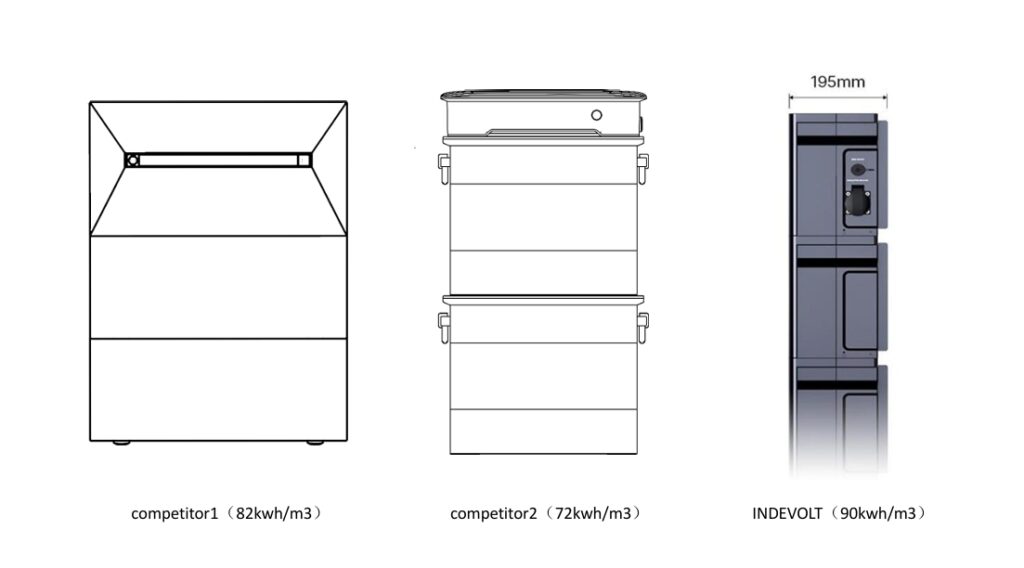

5.4 Energy Density Leap

Semi-solid batteries significantly improve energy density by:

- Reducing liquid electrolyte ratio

- Introducing solid electrolyte coating

This allows for:

- Use of higher-capacity electrode materials

- Reduced volume of inactive materials

- Optimized internal battery space

Additionally, the system adopts high-capacity cells, reducing the need for parallel connections and simplifying integration—shrinking overall system size.

Industry Volume Comparison (kWh/m³)

| Brand | Volume Energy Density |

|---|---|

| Competitor 1 | 82 kWh/m³ |

| Competitor 2 | 72 kWh/m³ |

| INDEVOLT | 90 kWh/m³ |

6. Outlook: From Balcony Systems to a Zero-Carbon Lifestyle

Semi-solid LFP batteries, by replacing part of the liquid components with solid-state electrolytes, are shaping the future of safe, efficient, and durable energy storage.

In the future, as every safe, high-performance semi-solid-state battery becomes part of household balconies, we will witness the seamless integration of green living and smart grids.

SolidFlex 2000 is a compelling choice for those seeking a safer, more economical, and flexible balcony energy storage system. Its innovative use of semi-solid-state LFP batteries not only enhances energy storage efficiency but also deepens the commitment to safety and sustainability.